Product Description

Single Screw Parallel Shaft Reducer for Plastic Extruder (JHM/ ZLYJ/ ZSYJ)

PTT extruder gearboxes have 2 popular series for 2 types screw extruders:

ZLYJ/ZSYJ Series Extruder Gear Units for Single Screw Extruders

SZ Series Extruder Gear Units for Conical Twin Screw Extruders

For parameters of SZ series gearbox and other extruder gearboxes applications, please consult our sales representatives and engineers.

Components:

1. Housing: Cast Iron or Steel Plate Welding

2. Gear Set: Hardened Helical Gear Pairs, Carburizing, Quenching, Grinding, Gear Hardness HRC54-62

3. Input Configurations:

Keyed CHINAMFG Shaft Input

4. Output Configurations:

Hollow Shaft Output

Models:

ZLYJ112~ZLYJ630

ZSYJ450~ZSYJ630

Features:

1. High strength alloy steel gears and shafts, sturdy and wearable

2. Hollow output shaft integrated with strong thrust bearings to withstand axial force of the screw

3. Large load capacity, superior performance for screw extruders applications

4. High efficiency, high reliability, long service life, low noise

5. Optional international brands of bearings and oil seals (ZheJiang CHINAMFG Oil Seals)

Applications:

Plastic Extruders

Rubber Extruders

Single Screw Extruders (ZLYJ/ZSYJ Series Extruder Gearbox)

Conical Twin Screw Extruders (SZ Series Extruder Gearbox)

Installation:

Horizontal Mounted

Vertical Mounted

Lubrication:

Oil Dip and Splash Lubrication

Forced Lubrication (Additional Oil Pump)

Cooling:

Natural Cooling

Auxiliary Cooling Devices

Company Introduction

Get the right gearbox for your equipment.

PTT knows gearbox. As the leading industry gearbox manufacturer, PSS offers the best power transmission solutions to perfectly meet your specific industry application. On gearbox, CHINAMFG has a lot more to share.

We always satisfy all industries with our gearbox

PTT strives for 100% satisfaction from customers of all industries. We welcome challenges to offer tailored design or special solution to satisfy customers’ Special needs on applications. We like to make impossibility become possibility.

Key features

Turbine gearboxes and planetary gearboxes are our advantages. Most companies can only manufacture Helical Bevel gearboxes, and we have a strong design team that has now designed turbine gearboxes up to 70, 000 rpm.

Diversity

PTT offers a vast diversity of gear reducer, geared motor and gearbox. No doubt you are able to find what you need with PTT.

Reliability

PTT is a trustworthy manufacturer you can rely on, no matter in terms of quality, delivery, pricing, service, etc. It becomes our name tag during our history of servicing our customers.

Capability

PTT is able to manufacture 200, 000 sets of gear reducers yearly and keeps investing on development of new series product.

We have a large list of our satisfied clients

Among the large list of our satisfied clients, there are many trend-setting top brands in various industries.

Mian products

Helical Gear Units

Bevel-Helical Gear Units

ZYJ Series Gear Units

DY Series Gear Units

P Planetary Gear Units

MLX Series Mill Gear Units

High Speed Gear Units

Non-stand Gear Units

RFQ

Q:Are you trading company or manufacturer?

A: We are manufacturer with over 20 years’ experience.

Q: How long is your delivery time?

A: Generally it is within 10 days if the goods are in stock, for goods produced as per order, it is within 35 days after confirmation of order.

Q: How long should I wait for the feedback after I send the enquiry?

A: Normally within 12 hours.

Q: What information should I give you to confirm the product?

A: Model/Size, Transmission Ratio, Speed, Shaft directions & Order quantity etc.

Q: Hong long is your product warranty?

A: We offer 12 months warranty from departure date of the goods.

Q: What is your payment terms? T/T 100% in advance for amount less than USD10000.-, 30% T/T in advance , balance before shipment for amount above USD10000.

If you have any other questions, please feel free to contact us below:

HOW TO CONTACT US?

Send your Inquiry Details in the Below, click “Send” Now!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Agricultural Machinery, Plastic and Rubber Extrusion |

|---|---|

| Function: | Change Drive Torque, Speed Changing, Speed Reduction |

| Layout: | Helical |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Are screw gears suitable for high-torque applications?

Using screw gears, also known as worm gears, in high-torque applications requires careful consideration. The torque capacity of screw gears can be a limiting factor due to their unique design and characteristics. Here’s a detailed explanation of the suitability of screw gears for high-torque applications:

Yes, screw gears can be suitable for high-torque applications, but there are certain limitations to consider:

- Lower Torque Capacity: Screw gears generally have a lower torque capacity compared to other gear types, such as spur gears or helical gears. The sliding contact between the worm gear and worm wheel, coupled with the high gear ratios typically associated with screw gears, can result in higher contact stresses and increased wear. Therefore, screw gears are generally not the first choice for applications with extremely high torque requirements.

- Efficiency and Heat Generation: In high-torque applications, the efficiency of the gear system becomes crucial. Screw gears, due to their sliding motion and higher friction compared to other gear types, can have lower mechanical efficiency. This lower efficiency leads to increased heat generation, which may be a concern in high-torque applications where heat dissipation becomes challenging. Proper lubrication, cooling, and heat management strategies are important to ensure reliable operation under high torque conditions.

- Load Distribution: The load distribution in a screw gear mechanism is not as uniform as in some other gear types. The load is concentrated on a limited number of teeth, which can lead to higher tooth stresses and potential wear. This concentration of load can be a limiting factor in high-torque applications, as it can result in premature gear failure or reduced lifespan.

- Application-Specific Considerations: While screw gears may have limitations in high-torque applications, there are scenarios where they can still be suitable. For example, in applications that require precise positioning, heavy loads, or the ability to hold position without additional braking mechanisms, the self-locking feature of screw gears can be advantageous. Additionally, advancements in gear design, materials, and lubrication can help improve the torque capacity and performance of screw gears in specific high-torque applications.

When considering the use of screw gears in high-torque applications, it is important to carefully evaluate the specific torque requirements, operating conditions, and other factors such as speed, duty cycle, and environmental considerations. Consulting with experienced engineers and conducting thorough analysis will help determine whether screw gears are suitable or if alternative gear types should be considered to meet the high-torque demands of the application.

How do you address thermal expansion and contraction in a screw gear system?

Addressing thermal expansion and contraction in a screw gear system is crucial to ensure the proper functioning and longevity of the system. Thermal expansion and contraction occur when a system is subjected to temperature changes, leading to dimensional changes in the components. Here’s a detailed explanation of how to address thermal expansion and contraction in a screw gear system:

- Material Selection: Choose materials for the screw gear system components that have compatible coefficients of thermal expansion (CTE). Using materials with similar CTE can help minimize the differential expansion and contraction between the components, reducing the potential for misalignment or excessive stress. Consider materials such as steel, bronze, or other alloys that exhibit good dimensional stability over the expected operating temperature range.

- Design for Clearance: Incorporate proper clearances and tolerances in the design of the screw gear system to accommodate thermal expansion and contraction. Allow for sufficient clearance between mating components to accommodate the expected dimensional changes due to temperature variations. This can prevent binding, excessive friction, or damage to the gears during temperature fluctuations.

- Lubrication: Utilize appropriate lubrication in the screw gear system to mitigate the effects of thermal expansion and contraction. Lubricants can help reduce friction, dissipate heat, and provide a protective film between the mating surfaces. Select lubricants that offer good thermal stability and maintain their properties across the expected temperature range of the system.

- Thermal Insulation: Implement thermal insulation measures to minimize the exposure of the screw gear system to rapid temperature changes. Insulating the system from external heat sources or environmental temperature fluctuations can help reduce the thermal stresses and minimize the effects of expansion and contraction. Consider using insulating materials or enclosures to create a more stable temperature environment around the screw gear system.

- Temperature Compensation Mechanisms: In certain applications, it may be necessary to incorporate temperature compensation mechanisms into the screw gear system. These mechanisms can actively or passively adjust the position or clearance between components to compensate for thermal expansion or contraction. Examples include thermal expansion compensation screws, bimetallic elements, or other devices that can accommodate dimensional changes and maintain proper alignment under varying temperatures.

- Operational Considerations: Take into account the thermal characteristics of the environment and the operational conditions when using a screw gear system. If the system is expected to experience significant temperature variations, ensure that the operating parameters, such as load capacities and operating speeds, are within the design limits of the system under the anticipated temperature range. Monitor and control the temperature of the system if necessary to minimize the effects of thermal expansion and contraction.

- System Testing and Analysis: Conduct thorough testing and analysis of the screw gear system under various temperature conditions to assess its performance and behavior. This can involve measuring dimensional changes, analyzing gear meshing characteristics, and evaluating the system’s ability to maintain proper alignment and functionality. Use the test results to validate the design, make any necessary adjustments, and optimize the system’s performance under thermal expansion and contraction effects.

- Maintenance and Inspection: Establish a regular maintenance and inspection routine for the screw gear system to monitor its performance and address any issues related to thermal expansion and contraction. This can involve checking clearances, lubrication levels, and the overall condition of the system. Promptly address any signs of excessive wear, misalignment, or abnormal operation that may be attributed to temperature-related effects.

By considering material selection, design clearances, lubrication, thermal insulation, temperature compensation mechanisms, operational considerations, and regular maintenance, it is possible to effectively address thermal expansion and contraction in a screw gear system. These measures help ensure the system’s reliability, minimize wear and damage, and maintain the desired performance and functionality over a range of operating temperatures.

What is a screw gear and how does it work?

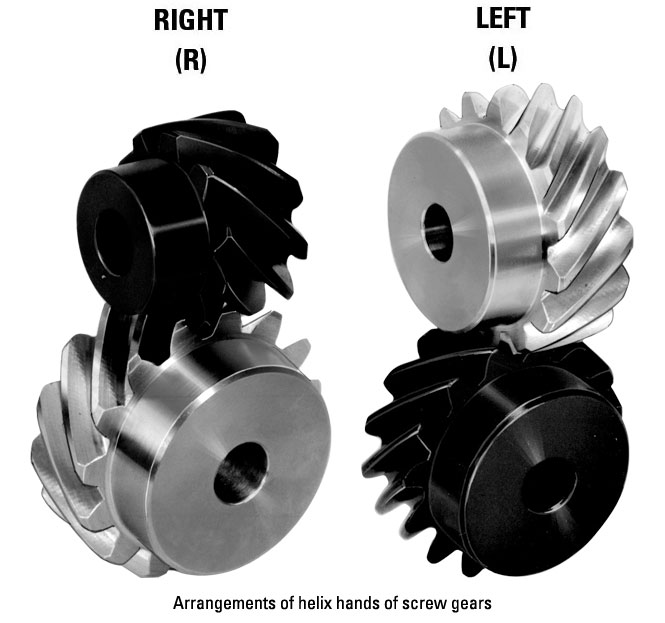

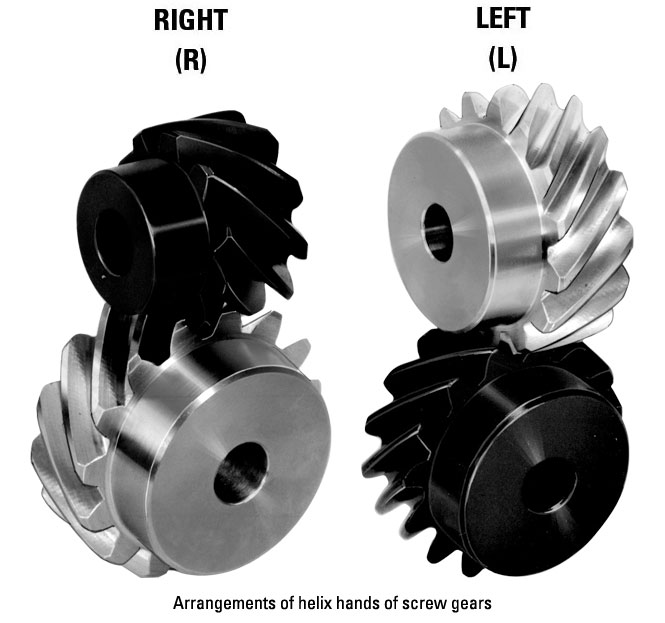

A screw gear, also known as a worm gear, is a type of gear mechanism that consists of a screw-like gear (called the worm) and a toothed wheel (called the worm wheel or worm gear). The screw gear operates on the principle of a helical screw driving a toothed wheel to transmit rotational motion and power. Here is a detailed explanation of how a screw gear works:

- Configuration: The screw gear consists of two main components: the worm and the worm wheel. The worm is a cylindrical gear with a helical thread wrapped around it, resembling a screw. The worm wheel is a toothed wheel that meshes with the worm. The orientation of the helical thread on the worm and the teeth on the worm wheel is typically perpendicular to each other.

- Meshing: The worm and the worm wheel mesh together by engaging the helical thread of the worm with the teeth of the worm wheel. The helical thread on the worm acts as a screw, and as the worm rotates, it drives the rotation of the worm wheel. The teeth on the worm wheel provide the necessary contact points for the meshing action.

- Transmitting Motion: When the worm rotates, the helical thread transfers rotational motion to the worm wheel. The helical thread of the worm pushes against the teeth of the worm wheel, causing the worm wheel to rotate. The direction of rotation of the worm wheel depends on the helix angle and the direction of rotation of the worm. The gear ratio between the worm and the worm wheel is determined by the number of teeth on the worm wheel and the pitch of the helical thread on the worm.

- Mechanical Advantage: One of the key characteristics of a screw gear is its ability to provide a high mechanical advantage or gear ratio. The helical design of the worm and the worm wheel allows for a large number of teeth to be engaged at any given time, resulting in a high gear ratio. This makes screw gears suitable for applications that require a significant reduction in rotational speed or an increase in torque.

- Self-Locking: A unique property of screw gears is their self-locking capability. Due to the helical thread design, the friction between the worm and the worm wheel tends to hold the gear system in place when the worm is not rotating. This self-locking characteristic prevents the worm wheel from backdriving the worm. It provides inherent braking or locking action, making screw gears suitable for applications where holding position or preventing reverse rotation is necessary.

- Efficiency and Lubrication: Screw gears generally have lower efficiency compared to other types of gears due to the sliding action between the helical thread and the teeth of the worm wheel. The sliding motion results in higher friction and heat generation. Proper lubrication is essential to minimize wear and improve efficiency. Lubricants with good adhesion and boundary lubrication properties are commonly used for screw gears.

Screw gears are widely used in various applications, including machinery, automotive systems, conveyor systems, lifting equipment, and many others. Their unique characteristics of high gear ratio, self-locking capability, and compact design make them suitable for specific applications where precise motion control, torque multiplication, or holding position is required.

editor by Dream 2024-05-13